About Feeding & Palletizing Technology

Our feeding and palletizing systems provide complete automation for material handling in packaging production. These intelligent systems feature advanced robotic precision positioning, seamless integration with die-cutting machines, and robust construction for high-speed operation. From automatic pre-feeders to AI-powered palletizing robots, our equipment streamlines your production workflow and maximizes efficiency.

JXB Robotic Arm Type Automatic Pre-feeder

A revolutionary pre-feeder powered by a KAWASAKI robotic arm. As the world-first technology by ODJ, it delivers unparalleled speed (up to 500 sheets/min), precision, and 100% damage-free handling for all board types.

QSL2 Slope Type Automatic Pre-feeder

A high-performance slope-type automatic pre-feeder designed for top print applications. Features advanced breaking unit for seamless integration with die-cutting machines.

QSL3 Baffle Type Automatic Pre-feeder

A reliable baffle-type automatic pre-feeder for top print applications. The workhorse of the production line with proven stability and efficiency.

QSL4/QSM Basket (Lifting) Type Universal Pre-feeder

A versatile basket (lifting) type universal pre-feeder suitable for various board types and production requirements. Offers excellent flexibility and reliability.

QXY3 Baffle Type Automatic Pre-feeder for Bottom Print

A specialized baffle-type automatic pre-feeder designed for bottom print applications. Ensures precise handling and positioning for high-quality printing.

BYS Semi-Automatic Pre-feeder

A cost-effective semi-automatic pre-feeder ideal for small to medium production volumes. Combines manual flexibility with automated efficiency.

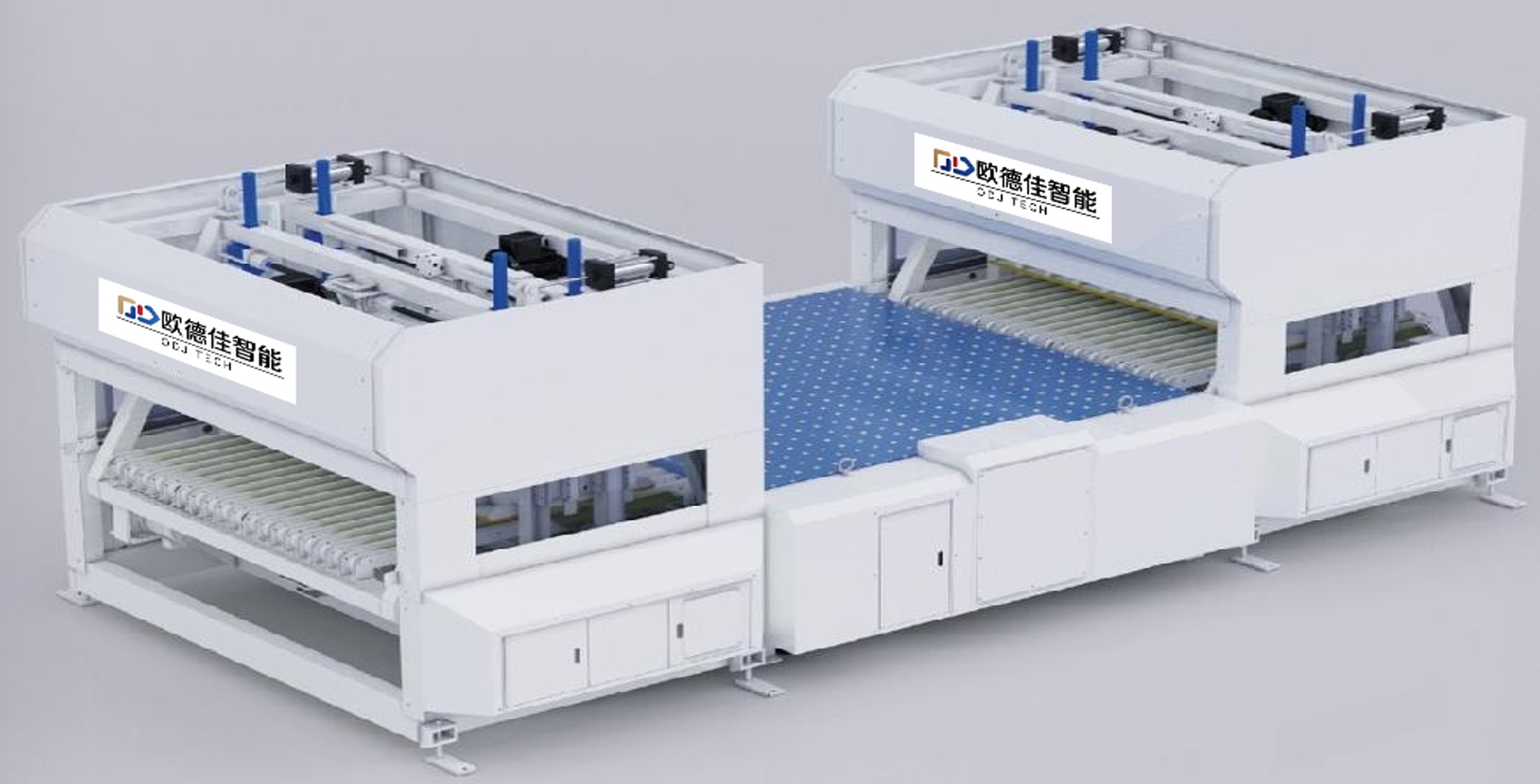

FP-1650 Automatic Bundle Breaker System

An advanced automatic bundle breaker system that efficiently separates corrugated board bundles, streamlining the feeding process and improving production efficiency.

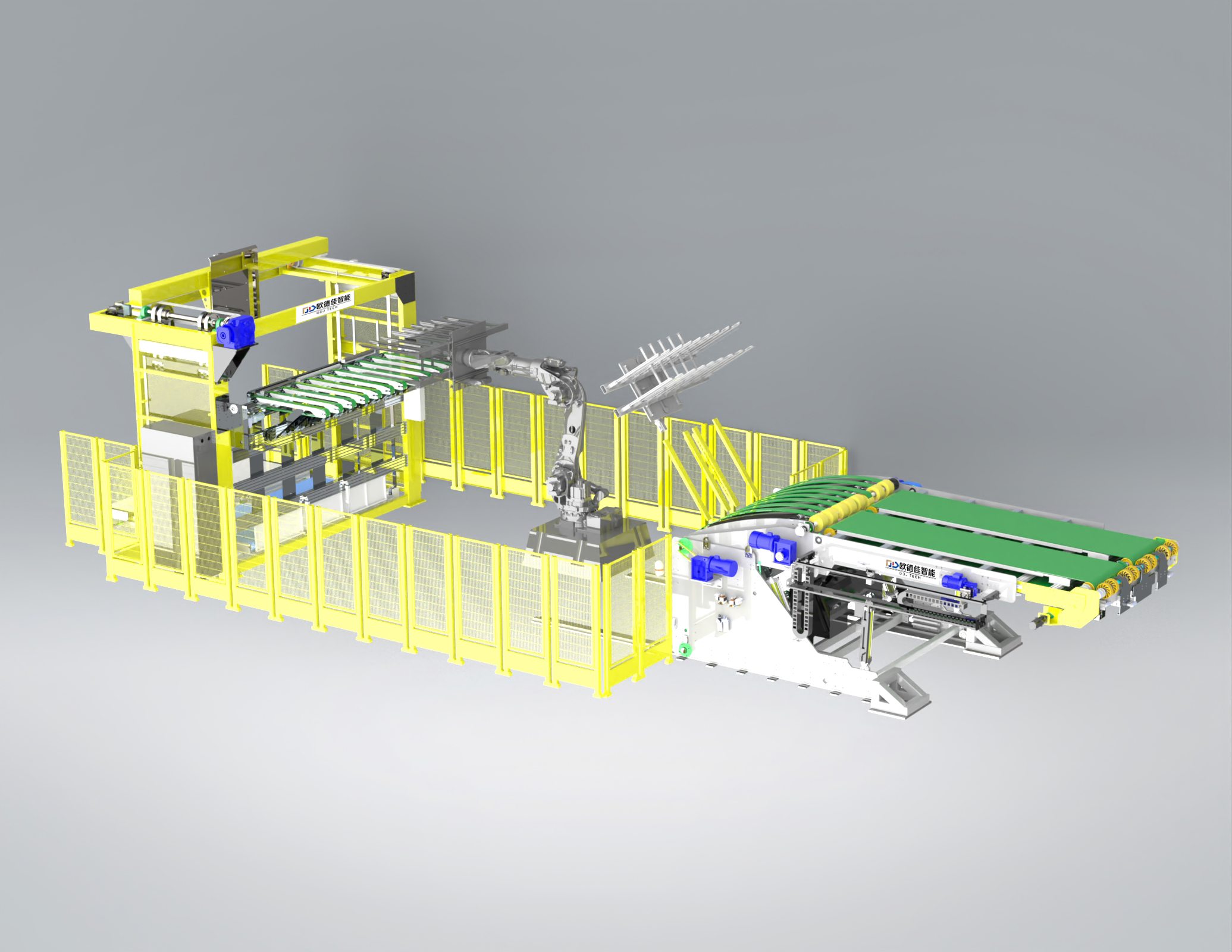

MD-350 3D Vision AI Intelligent Robotic Palletizing System

A state-of-the-art 3D vision AI-powered robotic palletizing system. Features intelligent stacking algorithms, real-time quality inspection, and seamless integration with production lines.